The Task Ahead

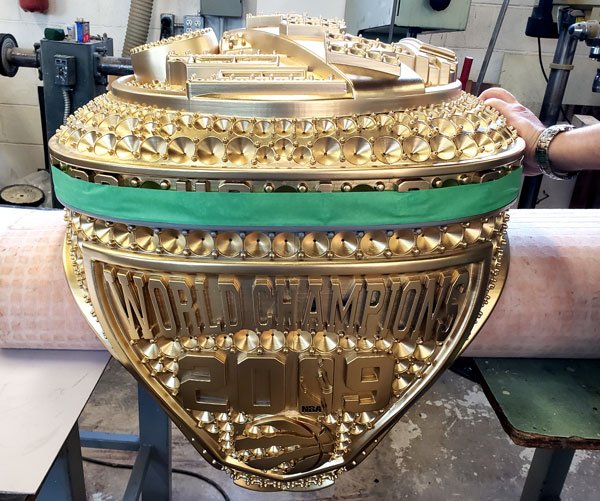

Over the past couple weeks we’ve been challenged with making a ginormous 15x scale replica of the new Toronto Raptors championship ring (& you thought the original was big).

The ring was unveiled in Jurassic Park during their pre-game ceremony and was placed on one of the two massive 14 foot tall hand sculptures.

Even from a far distance the ring sparkled high and bright drawing lots of attention as people flocked to get photos.

Building the Replica

After seeing the level of detail that was incorporated into the design of the ring, the nerves started to hit us. Each part of the ring told a unique story and we needed to mimic each feature accurately if we wanted it to be a true replica.

To better understand the level of difficulty we were dealing with, the Toronto Star put out an article outlining key features:

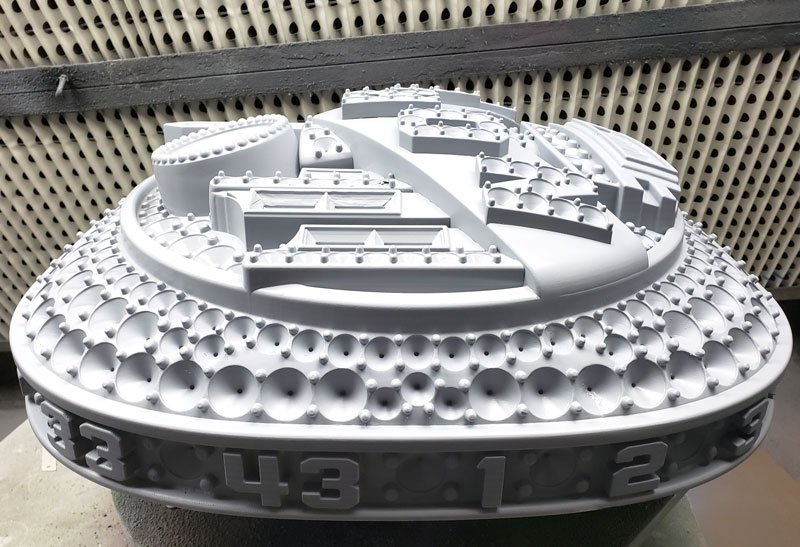

After viewing photo renders of the ring, we knew the best way to capture all the details was to have the ring 3D printed. 3D printing allowed us to create very complex shapes that would be nearly impossible to sculpt by hand.

In order to 3D print the main body of the ring, we needed to create the digital file based purely off of reference photos. After weeks of digitally sculpting using a modelling software, we finally had the file ready for 3D printing.

The ring was so big that we had to 3D print it in six different parts (even on our industrial sized machines). Below is some snapshots of the entire build process:

Each part was then assembled following a lengthy process of gluing, sanding, priming and painting (maybe a little body filler in between).

The diamonds were then lined up and tacked into place, a whooping 647 of them including 16 hand dyed rubies.

A special thanks to all the staff who were involved in this project and to Cobalt Fabrication Inc for helping make this all possible.

Cloudwalker

“Maplewing” – An innovative, Cost-Effective Fixed-Wing UAV

The Rocketeer Award – For the Prototype Prodigy 2025