DMLS Metal 3D Printing

Intricate, fully dense metal parts and complexity not achievable with CNC or casting

Quote request

DMLS Powder bed metal 3D printing, also known Selective Laser Melting (SLM), is a process in which a laser is used to melt and fuse metal powder layer by layer to create a solid object.

It is commonly used in aerospace, medical, dental, and automotive industries to create complex and customized parts.

Printed parts can be further modified by CNC machining or finished using any finishing technology for metals like powder coating, plating or high polishing.

Build size

up to 250x250x300 mm, 9.5” x 9.5” x 11.5”

Materials

Aluminum ASI10M6, Inconel 625, Maraging Steel MS1, Stainless Steel 316L, Corrax, Copper, Titanium

The Different Types of 3D Printing Technologies

3D printing has taken the manufacturing world by storm, transforming ideas into tangible objects with the simple click of a button. This incredible…

Read More

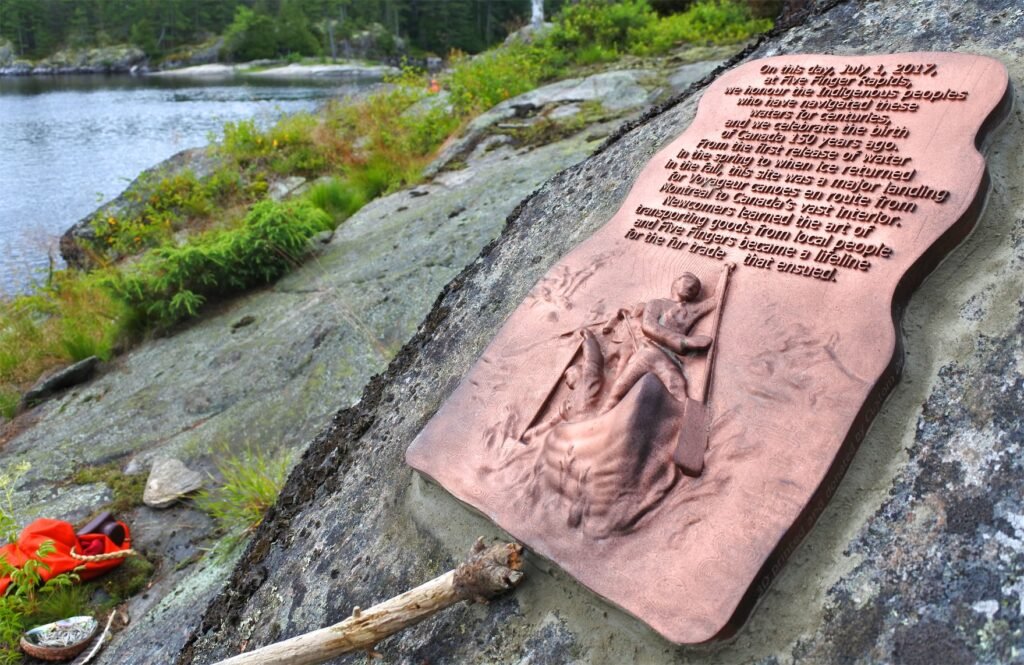

Transforming Interiors with Metal 3D Printing

Every day at Custom Prototypes we have the pleasure of working with some of the most innovative minds around. While we love working…

Read More

Metal 3D Printing Like Never Seen Before – 1st Century Roman Helmet Build

(See Full Video Down Below) Over the past couple months we embarked on a journey to see just how far we could…

Read More

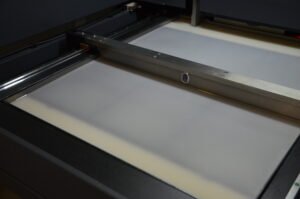

Size Matters

Some two months ago we took a delivery of a large 3D printer. It took us some time to set it up and…

Read More