First off, let’s talk about what you want from your 3D printed part. What is it used for? Is it a specific application or just for a general purpose? Will it undergo physical stress, fluctuating temperatures, exposure to UV light? Maybe you want a transparent part or to paint or dye it? The beauty of SLA printing is there is a plastic resin to compliment all your application needs.

The Process

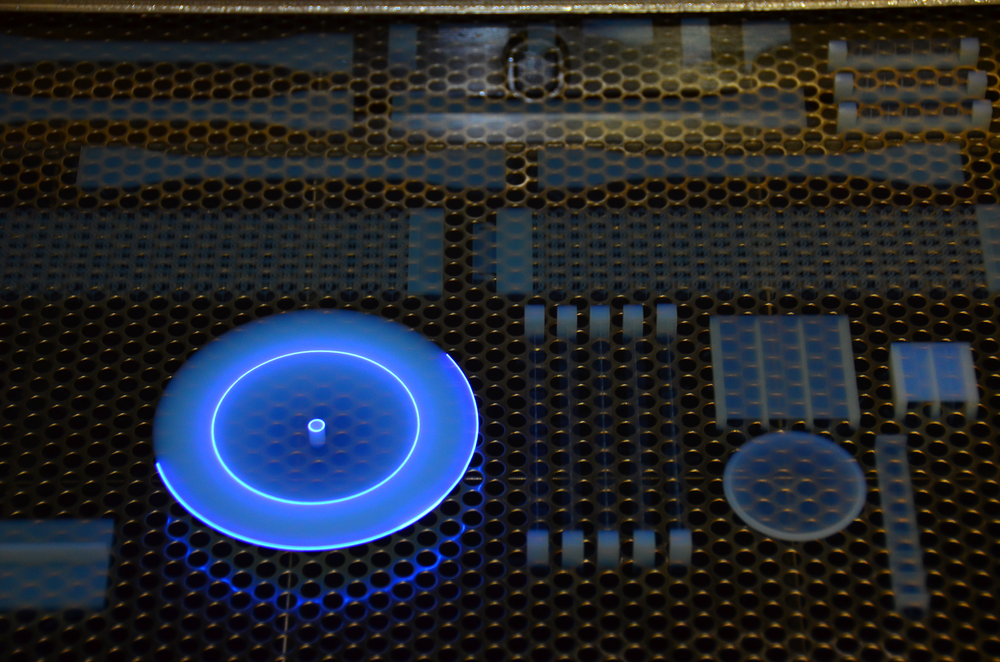

You may be thinking what is SLA? How does it differ from other 3D printing methods? The answer lies with its unique process that uses photopolymerization. Photo… what? Essentially, by casting a UV light on a photopolymer resin it causes it to solidify together which then creates your part. This allows you to print parts with high resolution at the pin point accuracy of a laser.

Benefits of SLA

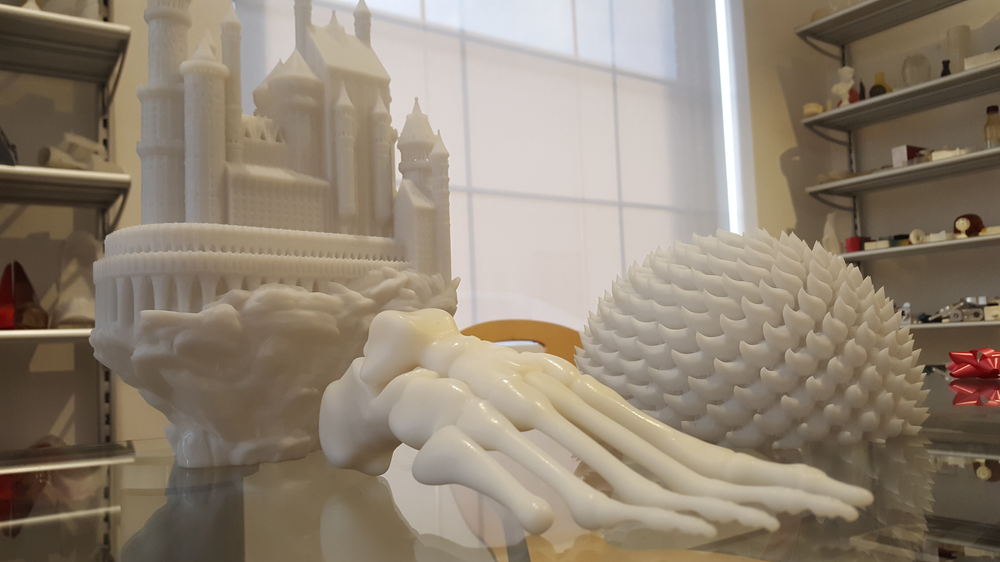

The main benefit with SLA printers is the ability to create complex parts without compromising the quality. Other extrusion 3D printing methods can be difficult to finish due to the visible layer stacking it creates. SLA is great for mocking up prototypes quickly and accurately with a range of materials that suits your project needs. Whether you want it to be sturdy and rigid, flexible and durable or a balance each, SLA printing is versatile enough to tackle almost anything.

Choosing the best SLA material for you

When it comes to choosing the right SLA material to print with it is best to understand what qualities you want your project to have. Here is a breakdown of three common SLA materials:

Somos Watershed Somos NeXt Somos EvolVe

What the professionals have to say

In 25 years I have ran a company that has been in the heart of this ever changing 3D printing industry called Custom Prototypes. We’ve done it all, printing and prototyping endless amounts of parts and models. One of the best decisions we ever made was purchasing our Z-rapid SLA machine. Since this investment we have been able to expand our cliental and fast tracked the timeline we can turnaround 3D printed parts. Our variety of printable materials allows our customers to choose exactly the kind of finish and material properties they want for their specific project.

The future of Canadian electric mobility with help from Custom Prototypes

And the Rocketeer Award Goes To…

Cloudwalker