Over the past three months our team at Custom Prototypes, a Toronto based rapid prototyping and 3D printing service company have been putting our design skills and equipment to work. Last year we captured 1st place at the AMUG annual technical competition and this year we plan on keeping that title.

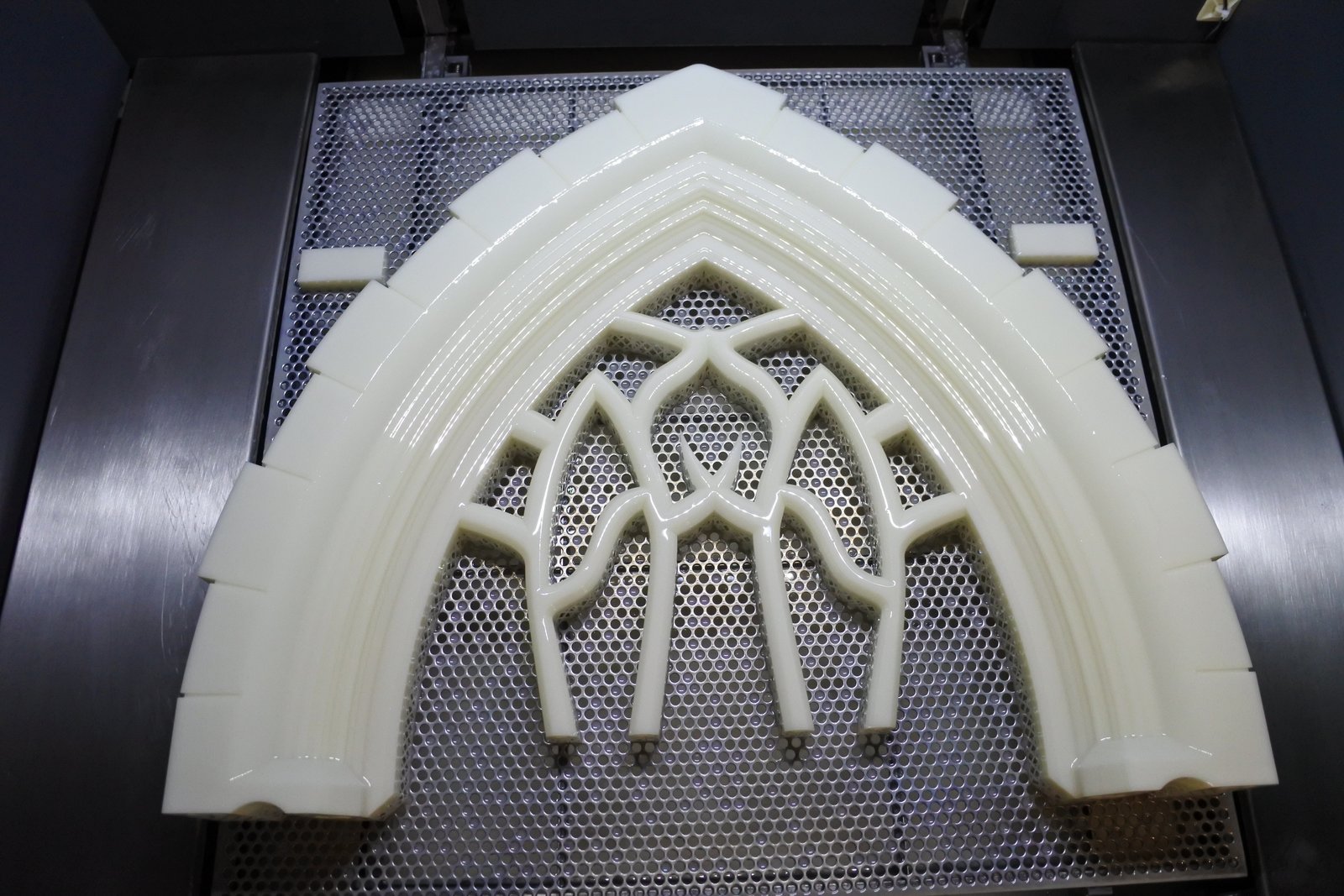

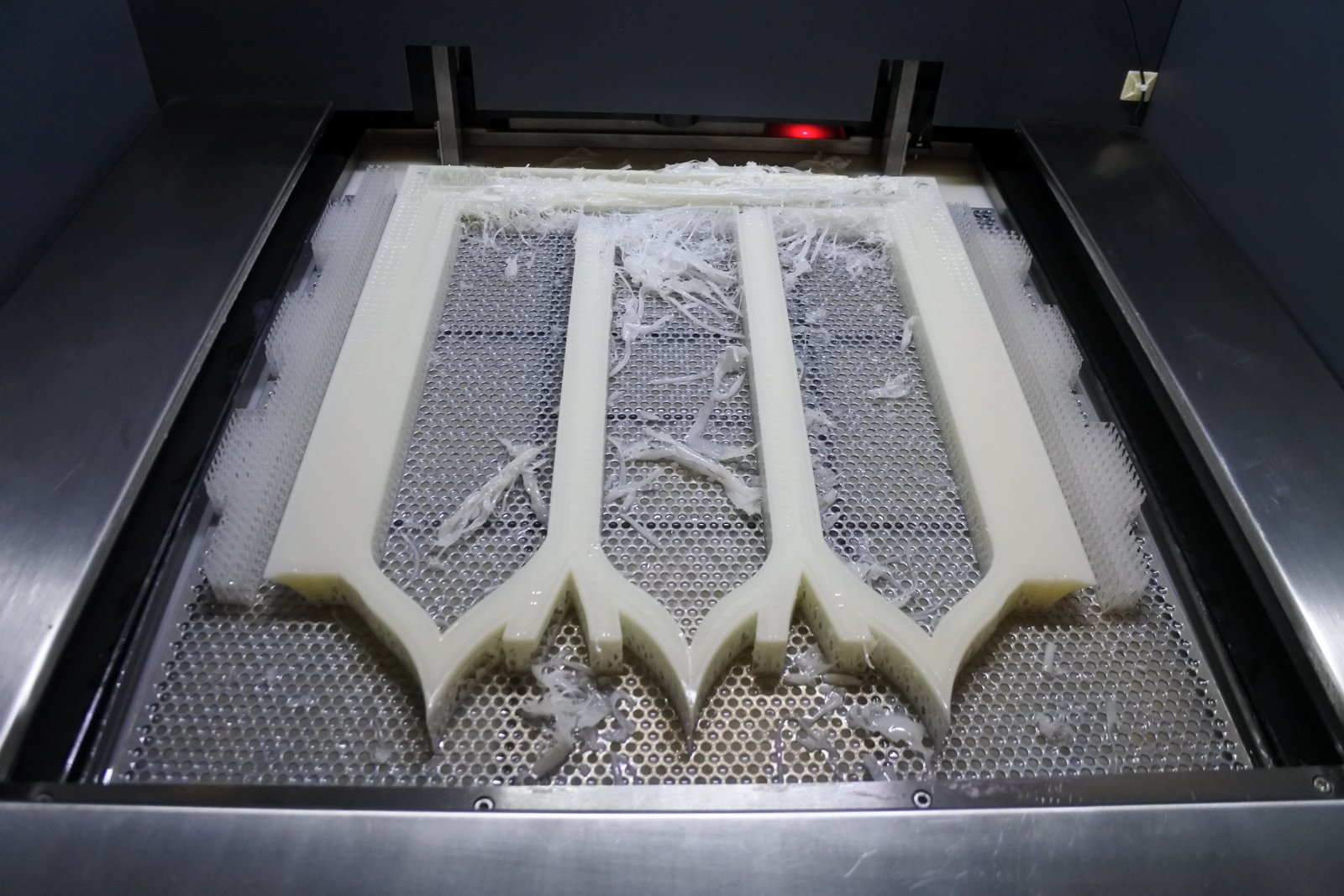

This year we wanted to put our SLA 3D printers to the test creating a full stained glass window out of 100% plastic. This project came to light with our ability to print in both solid and clear plastic using Somos resins.

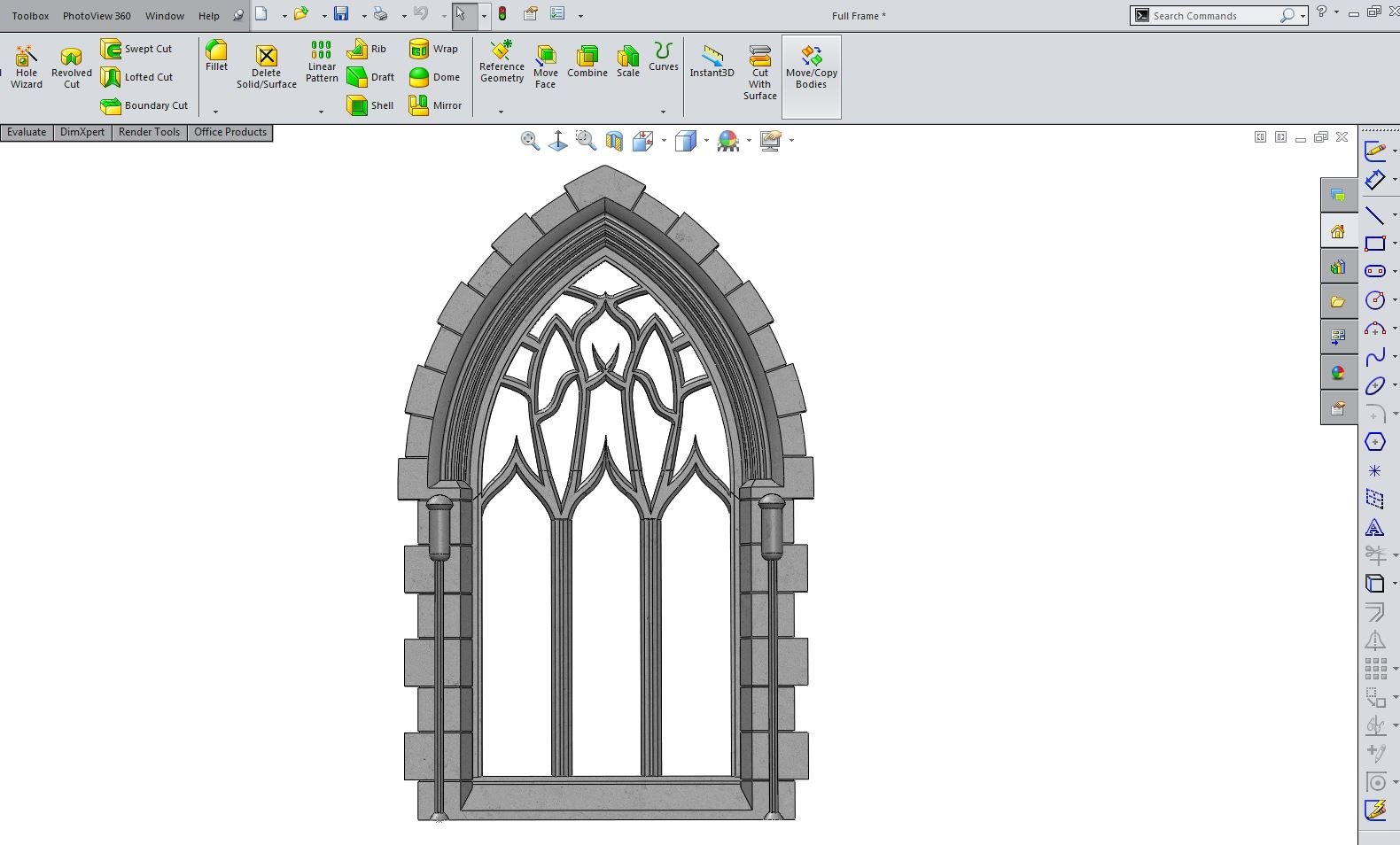

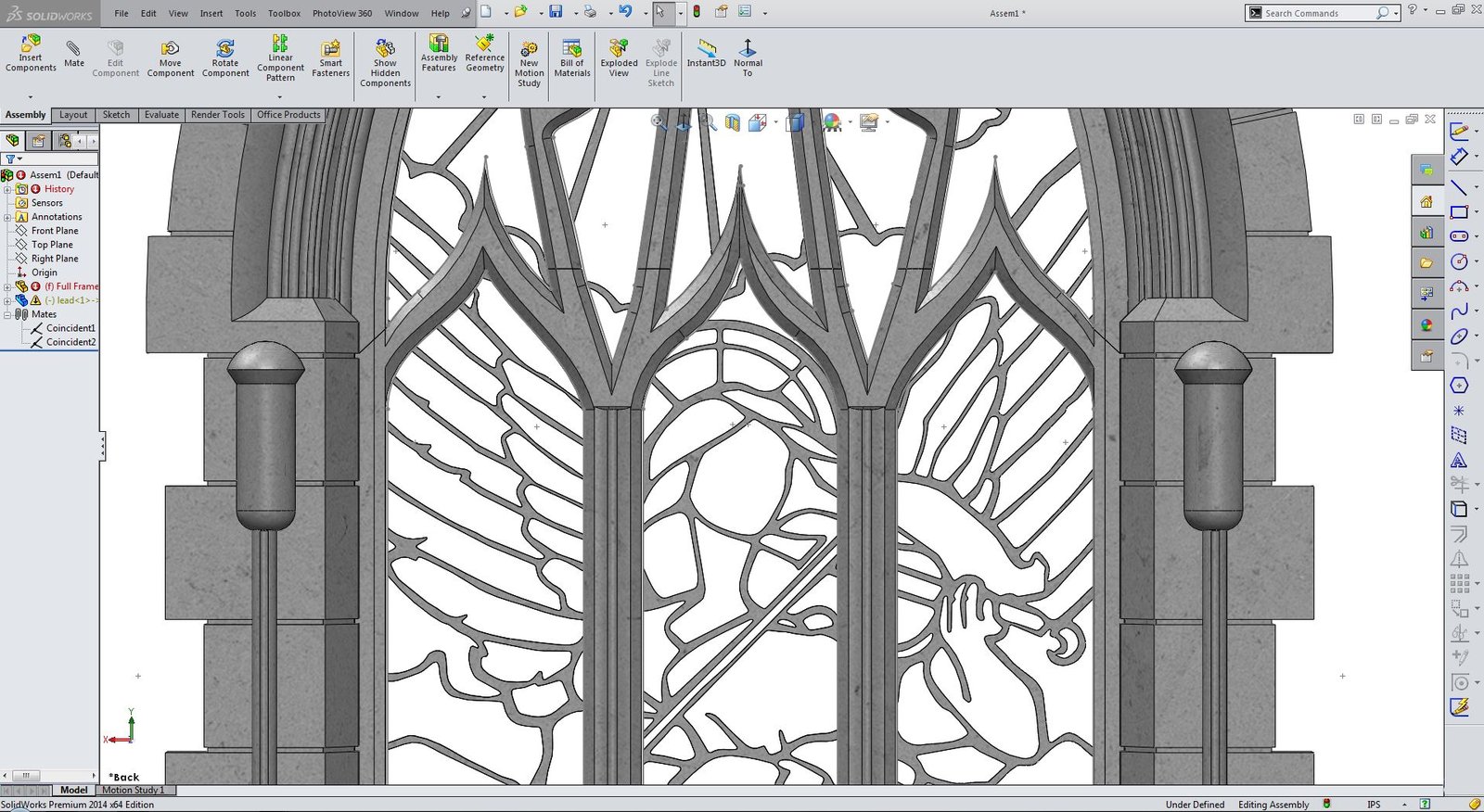

As the idea for the project unraveled, it was off to the computers where the entire window was designed using a 3D design software called Solidworks. Once the design was complete the whole window was then printed in four seperate pieces.

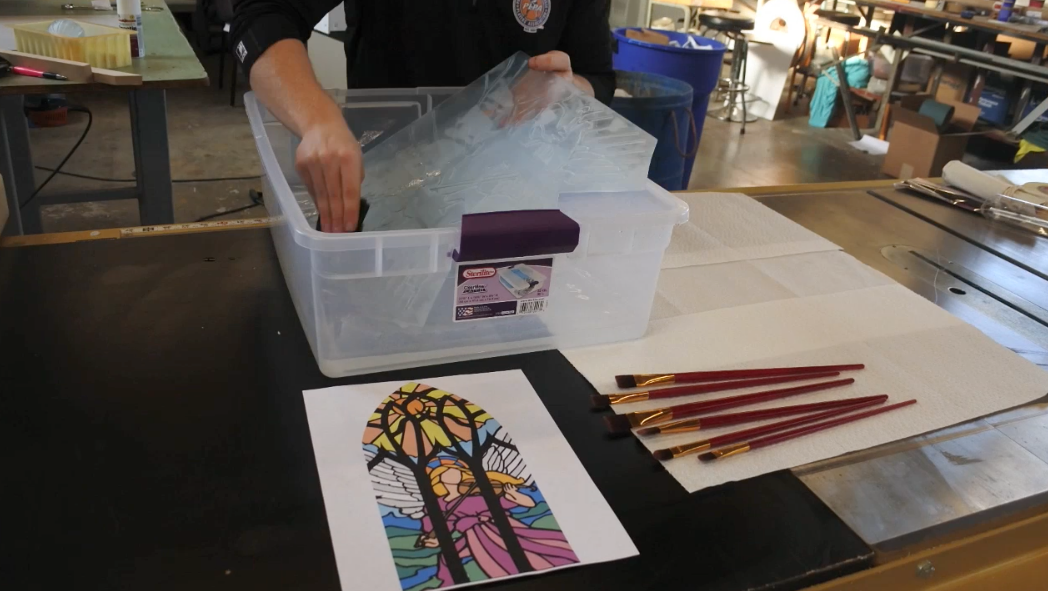

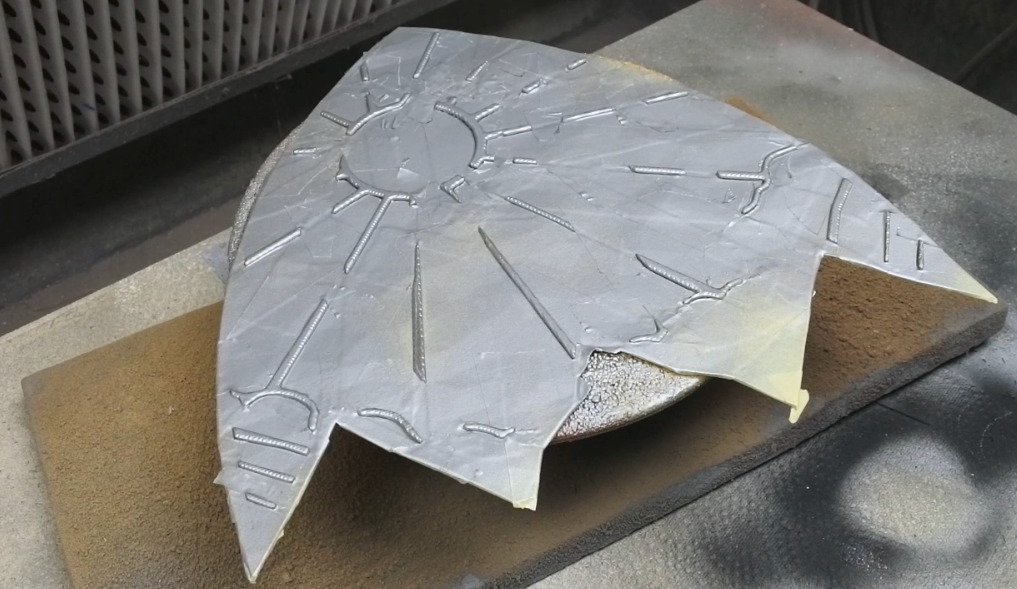

One of the biggest challenges was to create the appearance of coloured glass while still maintaining transparency. A lot of testing on scrap materials was required in order to assure the desired look could be achieved. Since paint came out too opaque, dye was used which required a tedious application process to avoid bleeding and mixing of neighbouring colours. With a generous amount of gloss clear coat afterwards, the desired look of ‘stained glass’ was obtained. The next step was to add on rustic lead lines, to do this we used a metallic spray undercoat with a black top coat and then textured it with steel wool.

The frame was then clamped, glued, sanded and all gaps were filled using body filler. The stone texture was achieved using various aerosol paints finished with a sandstone top coating.

Finally it was time for assembly, the stained glass was aligned and mounted to the frame resulting in the completion of the project.

Check out the video to see the full process

The future of Canadian electric mobility with help from Custom Prototypes

And the Rocketeer Award Goes To…

Cloudwalker