Every day at Custom Prototypes we have the pleasure of working with some of the most innovative minds around. While we love working with customers who know what they want, sometimes it’s nice to have the ability to flex our creative muscles and take a project from concept to final product.

About a month ago we had a very exciting and unexpected phone call come through our studio. The caller, an owner of a very successful interior design company, reached out to see if we could aid in the creation of a product for her dream home that she is currently working on.

She wanted her new house to push the envelope on traditional design and to create a space that isn’t just for function, but also tells a unique story of her life.

The request was to design a set of accessories for her new bathroom inspired by her childhood upbringing in Kashmir, India. The bathroom was designed to make you experience the feeling of being in a serene water garden.

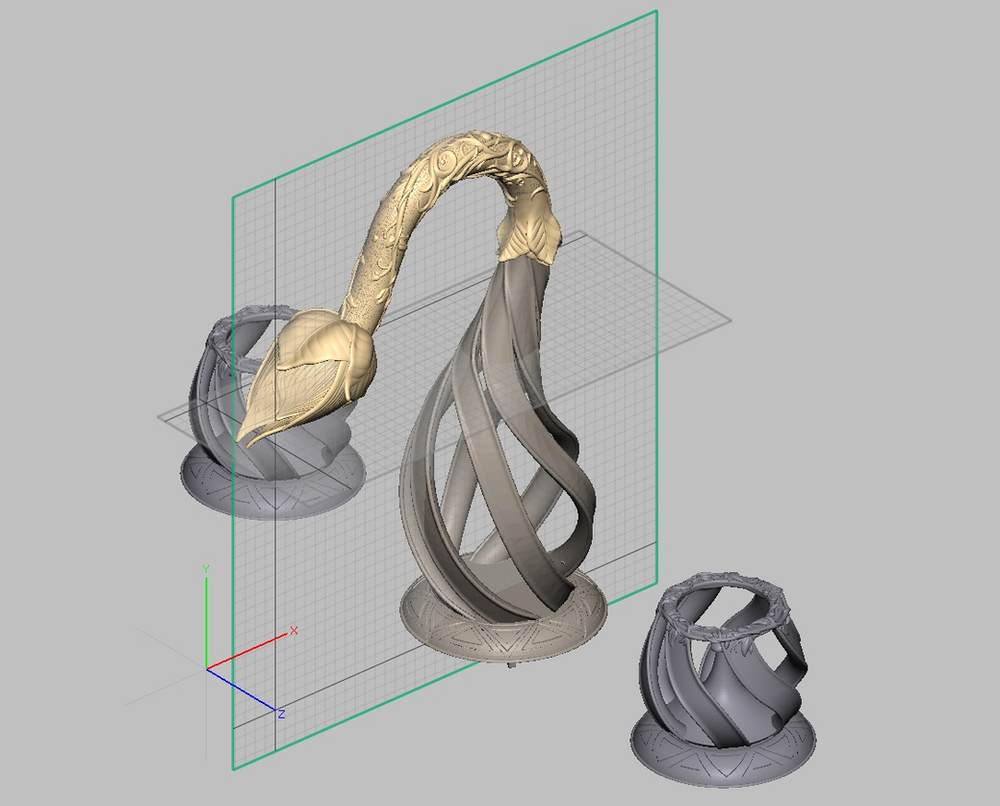

For this we wanted to incorporate the symbolic lotus flower and design a faucet that could act as a standalone art piece, even when not being used.

The work began on paper which consisted of endless rough sketches of abstract ideas, which then slowly lead us to a more refined concept. The sketches were then uploaded and manipulated digitally where we began to dial in the details and start sculpting the product on a software called Freeform.

One of the biggest challenges we had to face was to make sure the faucet not only achieved the aesthetic we were aiming for, but also making sure we could build it.

The water had to flow through six small channels at the base making it difficult to know if this would result in too much back pressure or resistance. Manufacturing methods like casting or CNC machining would render it impossible to achieve the hollow form that we were looking for thus making metal 3D printing the only option.

The faucet was 3D printed in stainless steel on a DMLS (direct metal laser sintering) machine. The whole part was printed with no internal support structures so the excess metal powder on the inside could easily be blown out.

Out of all the manufacturing processes available, this product could only be made through the use of metal 3D printing. This technology has broadened the scope of what’s possible and now acts as a powerful process in our maker toolkit.

If you have any questions about metal 3D printing or want us guide you in creating your own metal product, please get in touch with us at info@customprototypes.ca

The future of Canadian electric mobility with help from Custom Prototypes

And the Rocketeer Award Goes To…

Cloudwalker