Today 3D printing is one of the most rapidly growing technologies Efforts in the tech industry have made cheap 3D printing a possibility. In the past five years the hunt to develop an affordable 3D printer has become a popular endeavor.

n

n

Now the question arises, why does the cost of these 3D printers fluctuate so much? There are many 3D printing technologies to choose from that offer various materials and resolution quality which can make it confusing for the average consumer.

n

n

Here we compare two popular 3D Printing processes:

n

n

Stereo-lithography (SLA) vs. Fused Deposition Modeling (FDM).

n

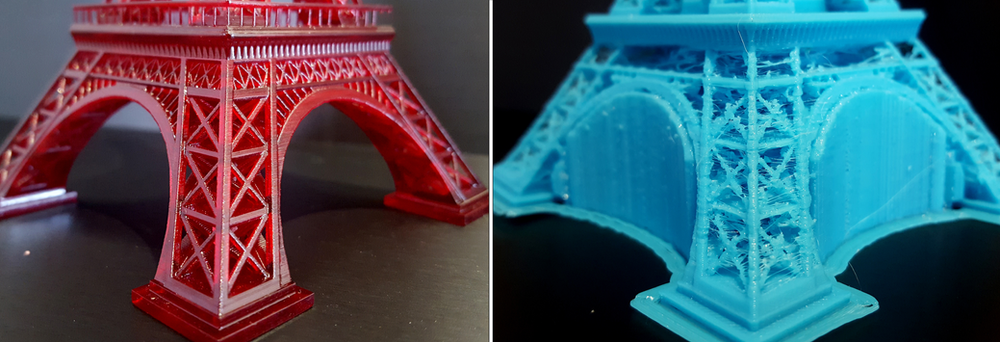

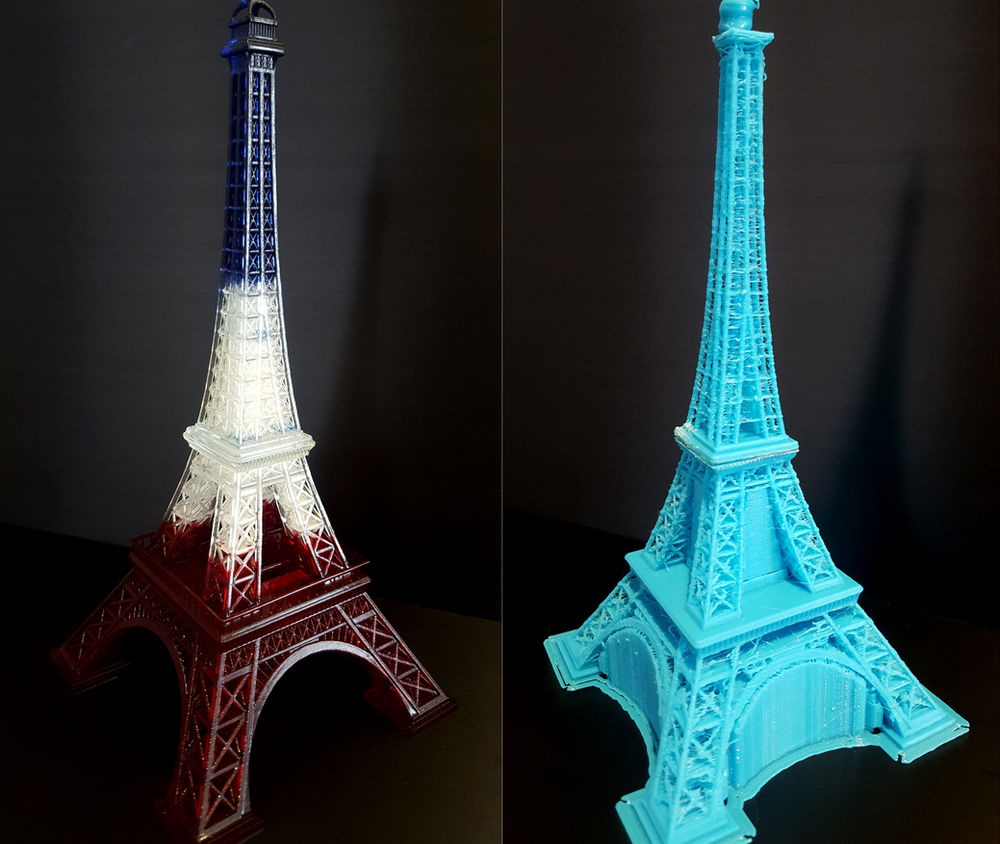

SLA FDM

n

n

Stereo-lithography was the first technology that was invented for 3D printing and even today is the most widely used process. SLA technology is great for functional parts that have very small tolerances. SLA printers work by casting a UV light on a photopolymer resin which causes it to solidify together which then creates your part. This allows you to create complex parts that involve very little finishing afterwards.

n

n

Fused Deposition modeling or FDM was introduced in late 1980’s and is the main reason for the price drop in 3D printing. This technology is employed mostly for DIY variants and less for a commercial purpose. This process works by feeding a plastic coil through a heated extruder stacking the layers of plastic which then creates your part. Creating complex shapes can be a challenge as this may require you to print a lot of plastic support in order to get your ideal shape. This technology may have upheld affordability but degraded the quality which a buyer would expect from a professional 3D printing service. This process is recommended for a cheap 3D printing solution for someone who doesn’t require absolute precision.

n

n

n

n

n

n

Cloudwalker

“Maplewing” – An innovative, Cost-Effective Fixed-Wing UAV

The Rocketeer Award – For the Prototype Prodigy 2025