At Custom Prototypes we have carried out various interesting projects with cutting-edge technologies like 3D printing, but seldom we get an opportunity to swirl around traditional yet effective technologies like Vacuum-forming. This is recently, when a customer came up with an idea to produce shades for light fixtures for an exquisite Bistro in Toronto. Initially it seemed quite arduous to produce the shades just from a napkin sketch. After thorough discussions, considering the geometry, material and the functionality we deduced to opt for Vacuum-forming. The goal was to form shades that match and compliment the ambience and atmosphere of the Bistro.

Contemplation and action work hand in hand, we were able to produce some elegant shades of sign-white Acrylic. The process was initiated by generating a tailored 3D design to produce a mould for vac-forming.

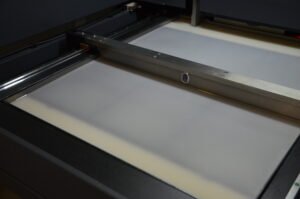

Simply, the process entails heating a plastic sheet until it is soft. The soft sheet is then draped around a mould to which vacuum is applied. The sheet then takes the shape of the mould.

The Different Types of 3D Printing Technologies

Transforming Interiors with Metal 3D Printing

Metal 3D Printing Like Never Seen Before – 1st Century Roman Helmet Build