High output with little input, this is the objective which all automotive manufacturers seek to achieve. With every disruptive technology comes along a new learning curve – where implementing these changes to the manufacturing process can aid in further productivity resulting in higher profits.

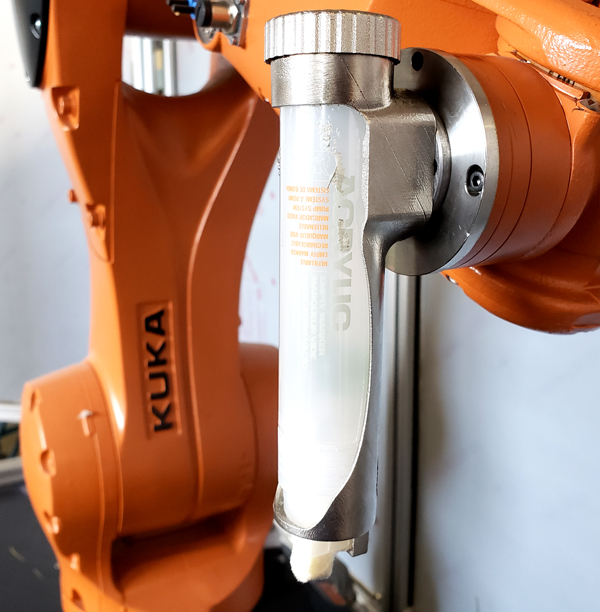

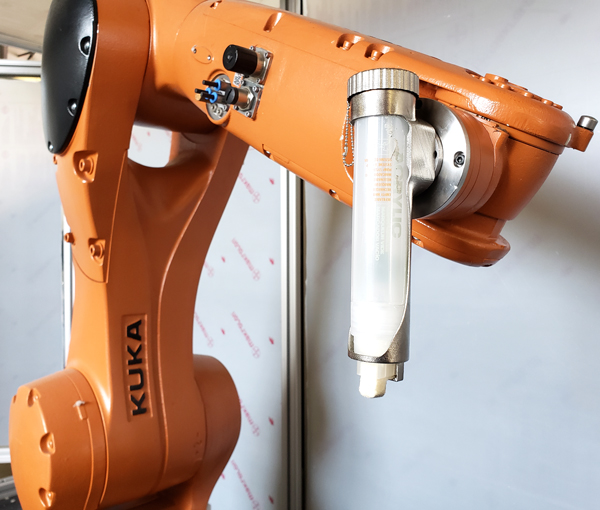

(Metal 3D printed robot end-of-arm tool)

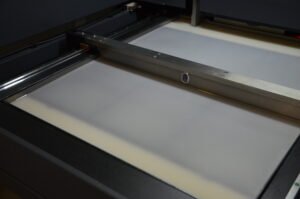

Over the years Custom Prototype’s has built strong working relationships with big automotive manufactures to assist in the post-processing of end-use parts. This often entails designing, engineering and fabricating custom jigs and fixtures which house the parts in order to endure further manipulation from a robot.

The “end of arm” is the industry name given to the robotic feature which performs these tasks found at the end of the robot. The end of arm tool is usually a custom made to perform a specific task such as welding, cutting, gripping punching holes etc.

A recent project required us to create a glue dispensary unit that would be used to apply controlled adhesive to automotive parts during the assembly process.

For projects that involve complex geometry, 3D printing is a viable solution as certain machining processes have limitations which could not achieve the desired shape.

In this case we needed a part that could perform strenuous tasks without compromising the structural integrity of the part. This guided us to metal 3D print the unit in 316 stainless steel metal.

The part was designed in Solidworks and 3D printed using a process DMLS (direct metal laser sintering). The machine used was Renishaw AM250 which is capable of producing parts down to a tolerance of 0.1mm

To see other unique applications for metal 3D printing check out our recent post on our 100% 3D printed metal helmet.

For more information on our metal 3D printing services see our other page here.

The Different Types of 3D Printing Technologies

Transforming Interiors with Metal 3D Printing

Metal 3D Printing Like Never Seen Before – 1st Century Roman Helmet Build