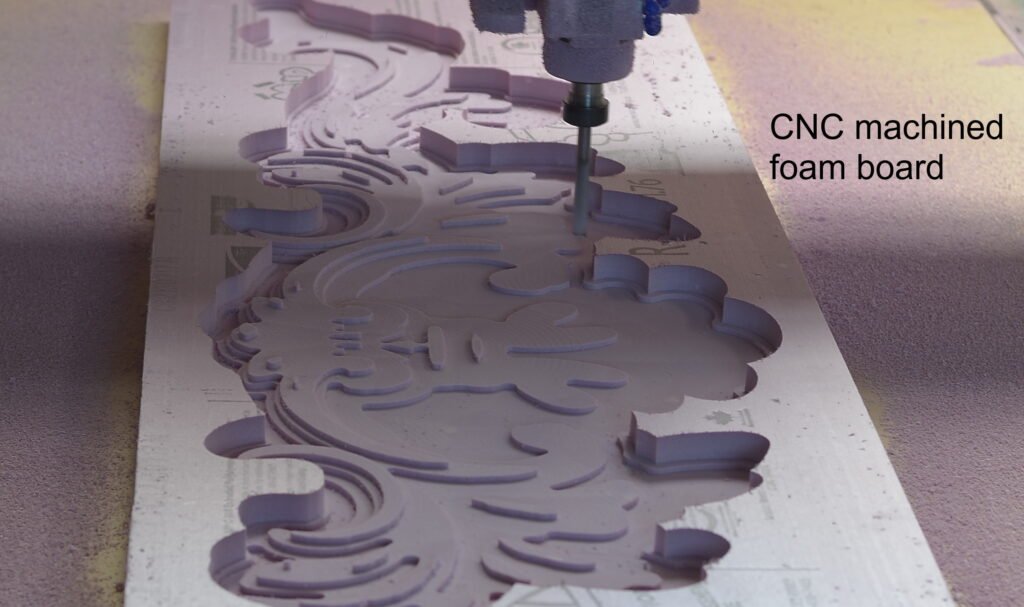

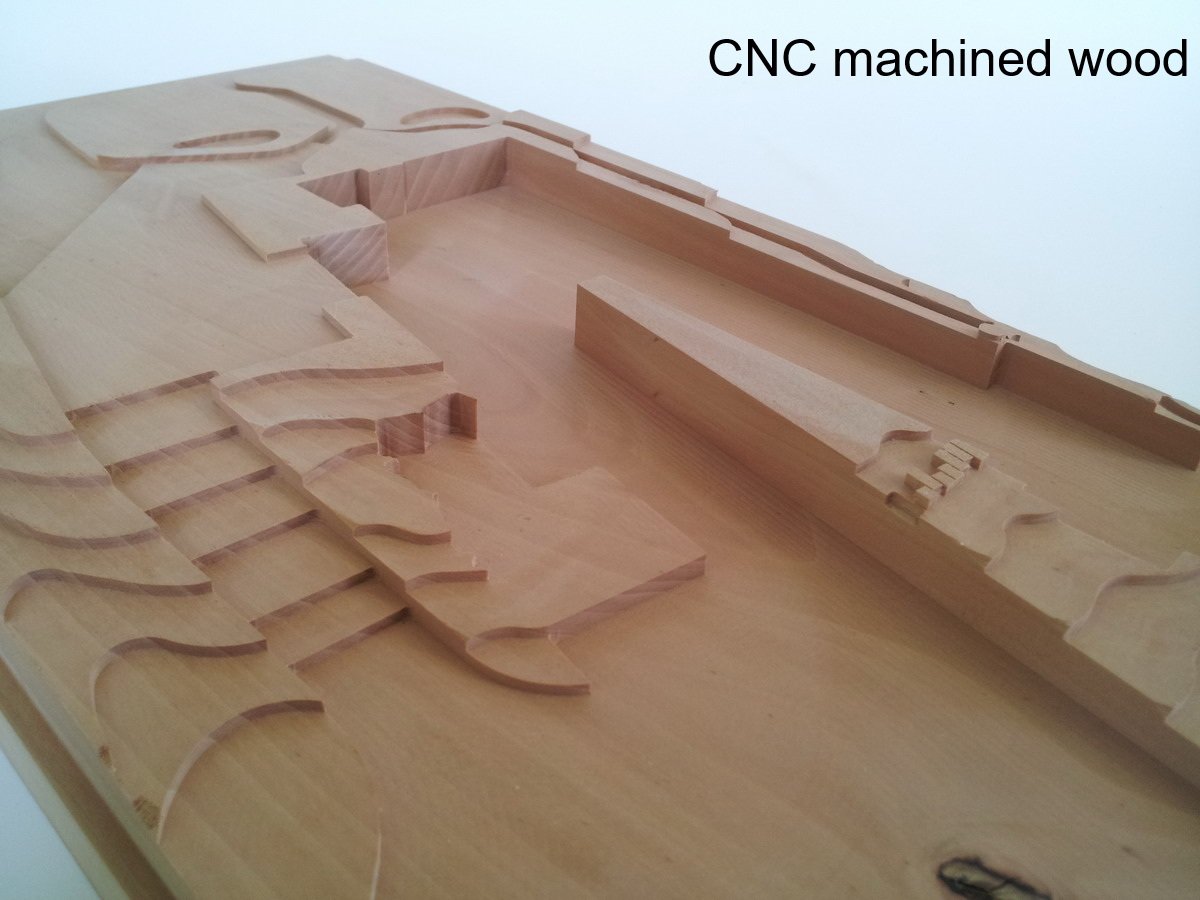

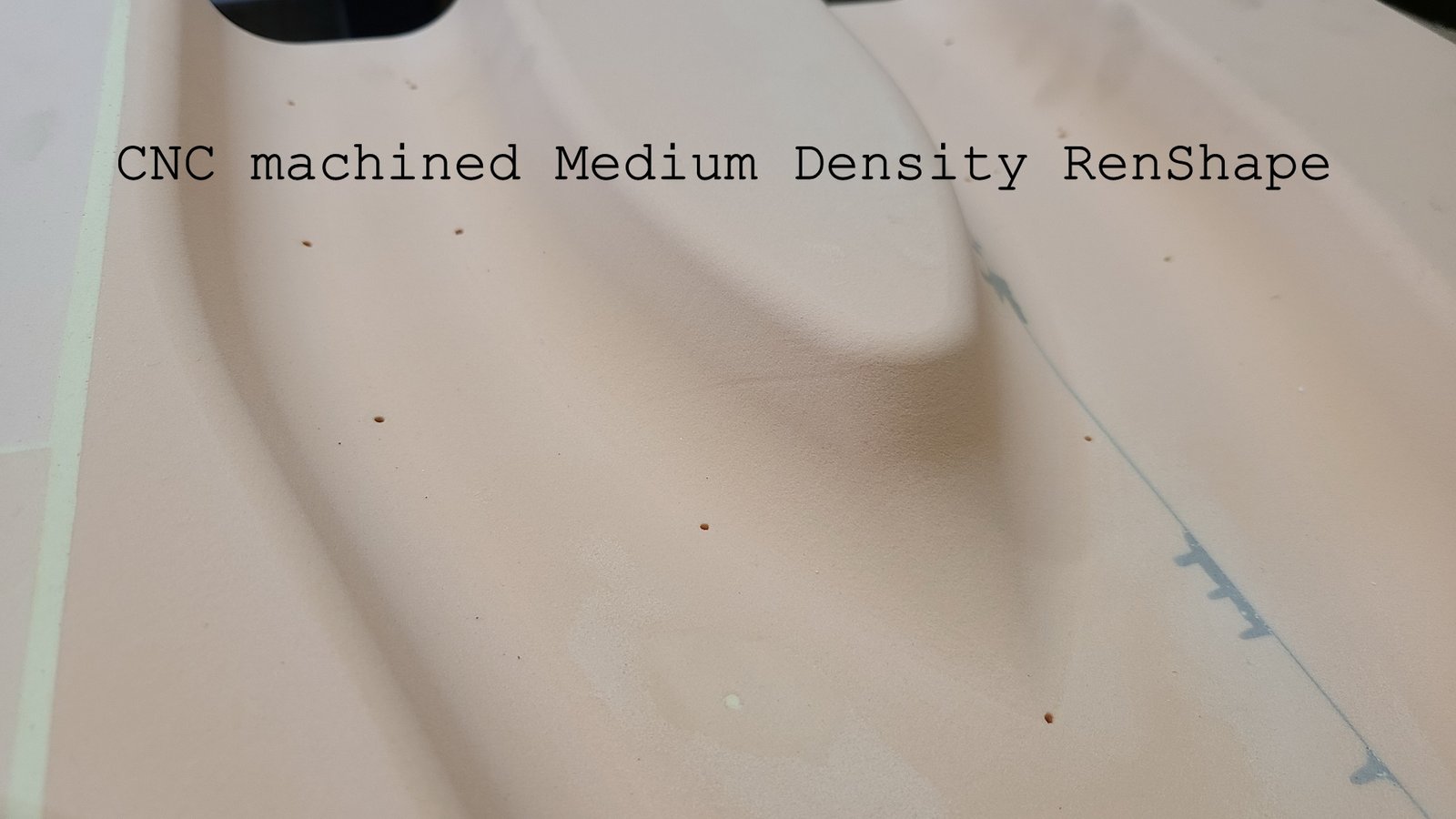

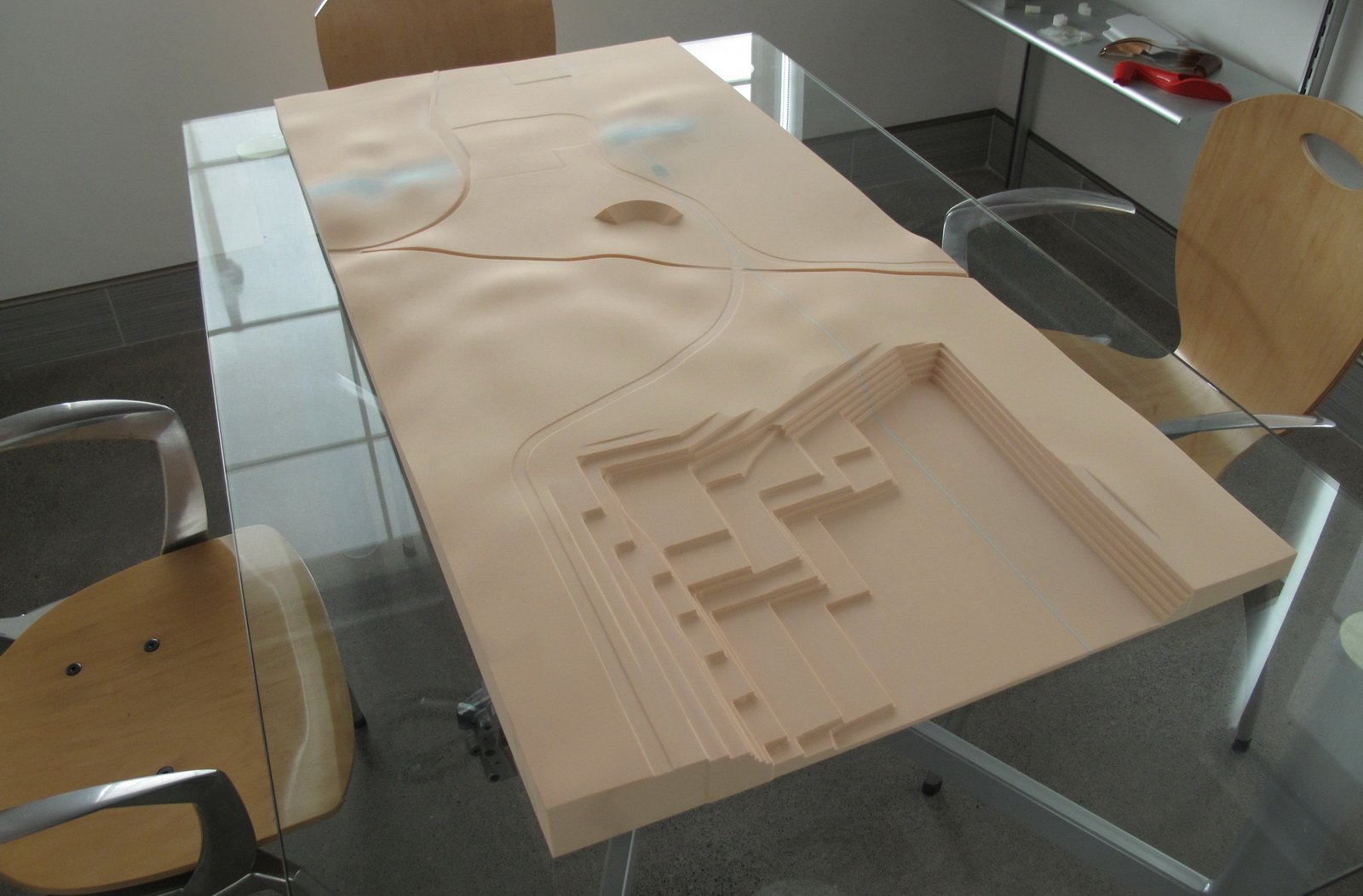

The most common technique used to manufacture molds, Computer Numerical Control (CNC) Machining creates complex parts using pre-programmed computer software to control machine tools such as lathes, drills, mills, routers, and grinders.

The smooth function of automated machines precisely produces 3D parts by assigning cuts to specified areas on various levels on the material.

Haas TL-1

3 Axis CNC vertical milling machine with machine table working size: 30”L x 12”W x 16”H

Capable of machining any machinable material like metals, plastics, ren shape

Haas TM-1

3 Axis CNC Lathe with machine table working size:

16”Diam. x 30” L

Capable of machining any machinable material like metals, plastics, ren shape

Router

3 Axis CNC Router with machine table working size: 96” L x 48” x 6”HCapable of machining any soft machinable material like plastics, ren shape, thin aluminum

Because CNC machining involves code written and revised by programmers, there is a significant investment depending on the complexity of the part. However, this process can accommodate a variety of angles, complexities, and materials which would be almost impossible to produce using manual machining methods.

Complete products are manufactured in one operation, eliminating the need for a multi-staged production, making CNC machining services an economical choice for complex, repeatable, and precise rapid manufactured parts.

The future of Canadian electric mobility with help from Custom Prototypes

And the Rocketeer Award Goes To…

Cloudwalker