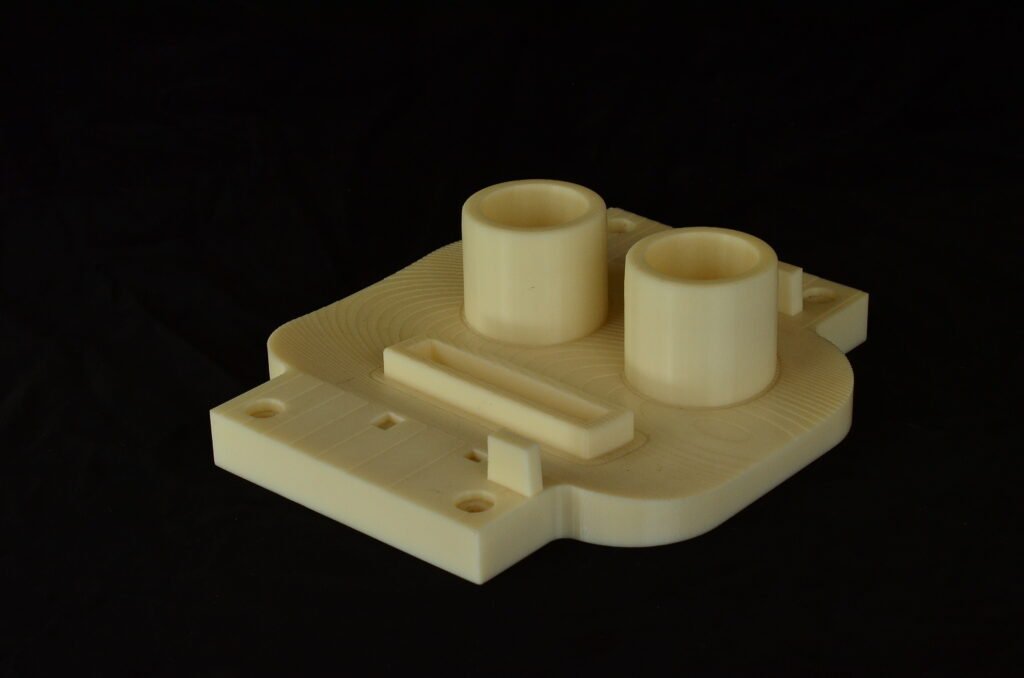

FDM 3D Printing

FDM (Fused Deposition Modeling) is a 3D printing process in which plastic is melted and extruded through a small nozzle to build up a model layer by layer.

Also known as FFF (Fused Filament Fabrication) this process creates prototypes that can endure the most extreme environments:

-

Continuous Use Temperature (CUT) of up to 275°C,

-

Exposure to all chemicals except sulphuric acids, mechanical stress.

Comparable only with composites and desirable FST (flame, smoke and toxicity) rating.

We recommend it for products in oil/gas, automotive, aerospace, industrial, medical and chemical processing industries. It’s best for parts that feature fairly solid structures.

Build size

300x300x400 mm, 11.8” x 11.8” x 15.7”

Materials / Specs

Engineering Plastics

ABS, ASA, PC, Nylon, PETG, PVDF, TPU, Carbon Fiber

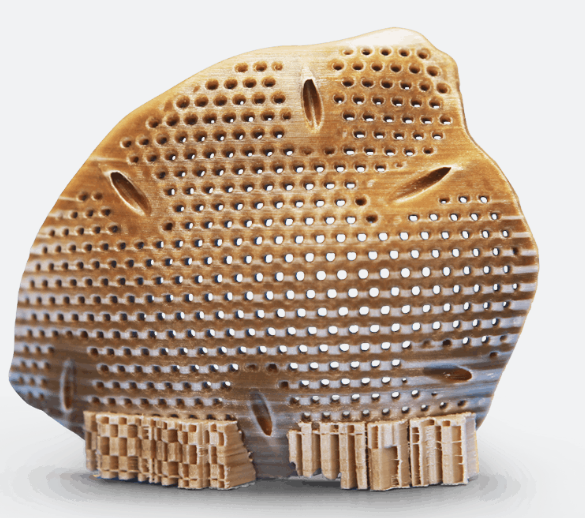

Strip and ship finish

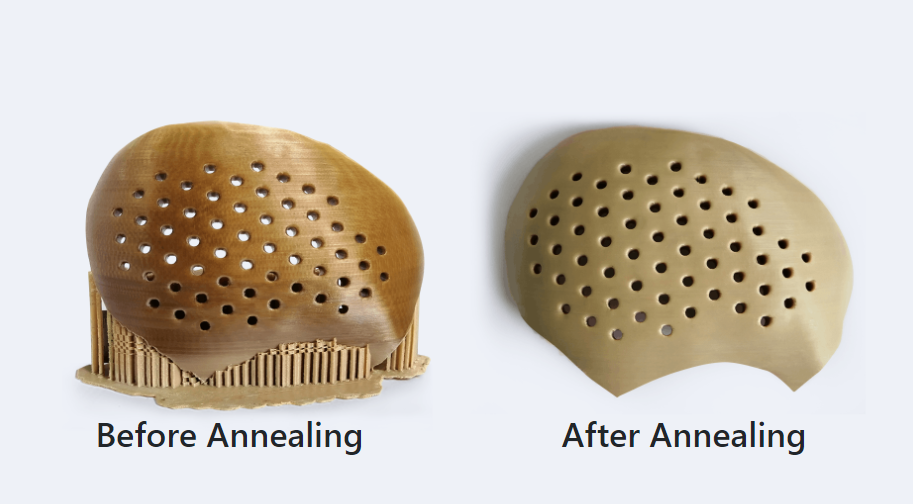

Before-After Annealing finish

The future of Canadian electric mobility with help from Custom Prototypes

And the Rocketeer Award Goes To…

Cloudwalker