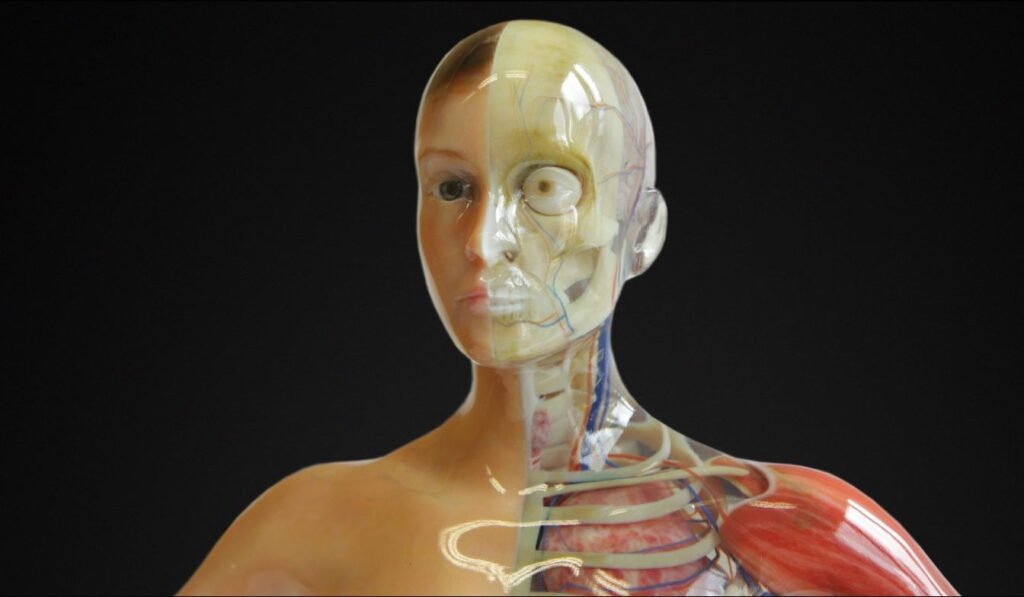

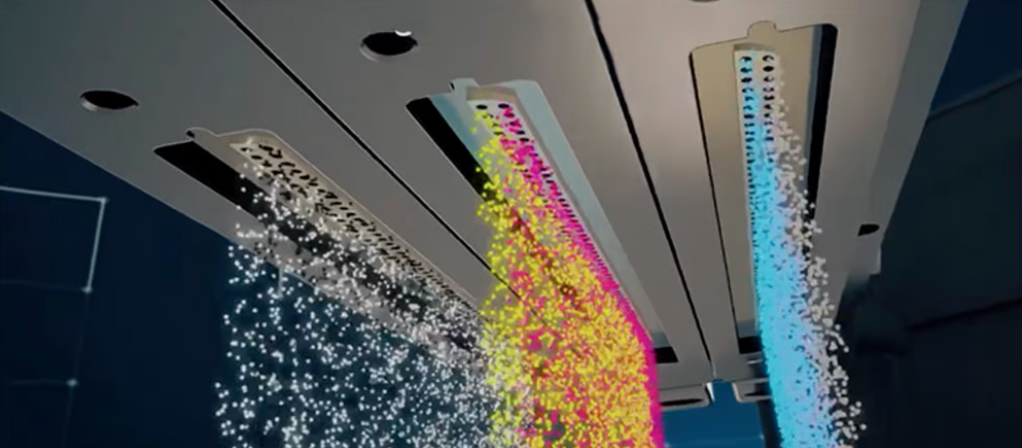

Our state-of-the-art Mimaki color 3D printing system produces parts using polymer-based material and an inkjet print head to build up layers and create a finished 3D object. The process uses 7 different resins, which are cured by UV light during the process. Mimaki's technology allows for precise control over the color and finish of the final product. Its digital color modeling with the capability 10 million colors is the highest in the industry.

Full-color modeling capabilities allow the production of the world’s first 10 million colors. The UV curing inkjet method achieves high-definition color expression that is about twice that of the binder jetting (plaster powder) method.

Build size

up to 203x203x76 mm, 8”x8”x3”

more than 10 million

30 Micron

1200 dpi

Clear ink for transparent and translucent effects

The future of Canadian electric mobility with help from Custom Prototypes

And the Rocketeer Award Goes To…

Cloudwalker