SLA 3D Printing Services

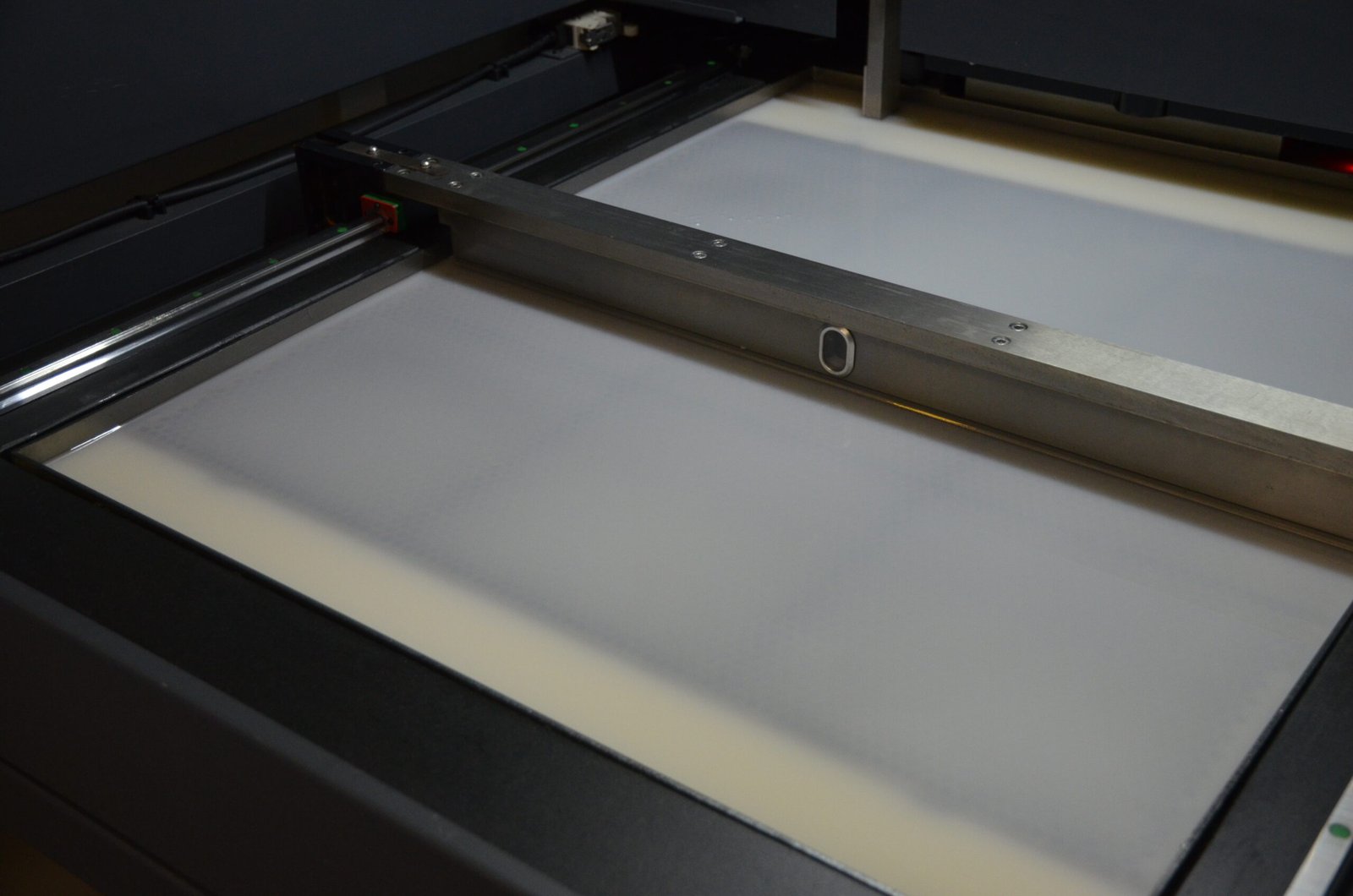

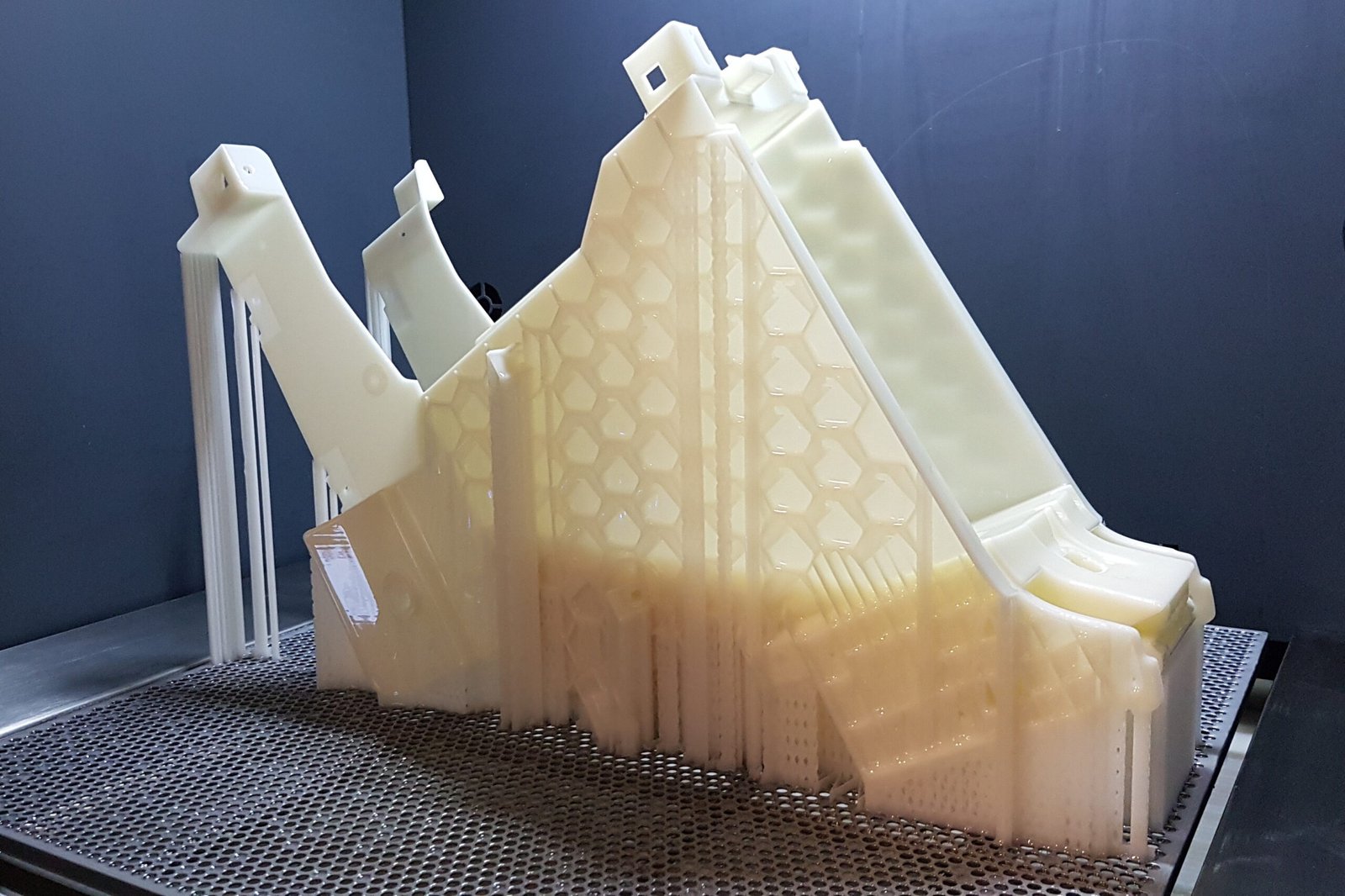

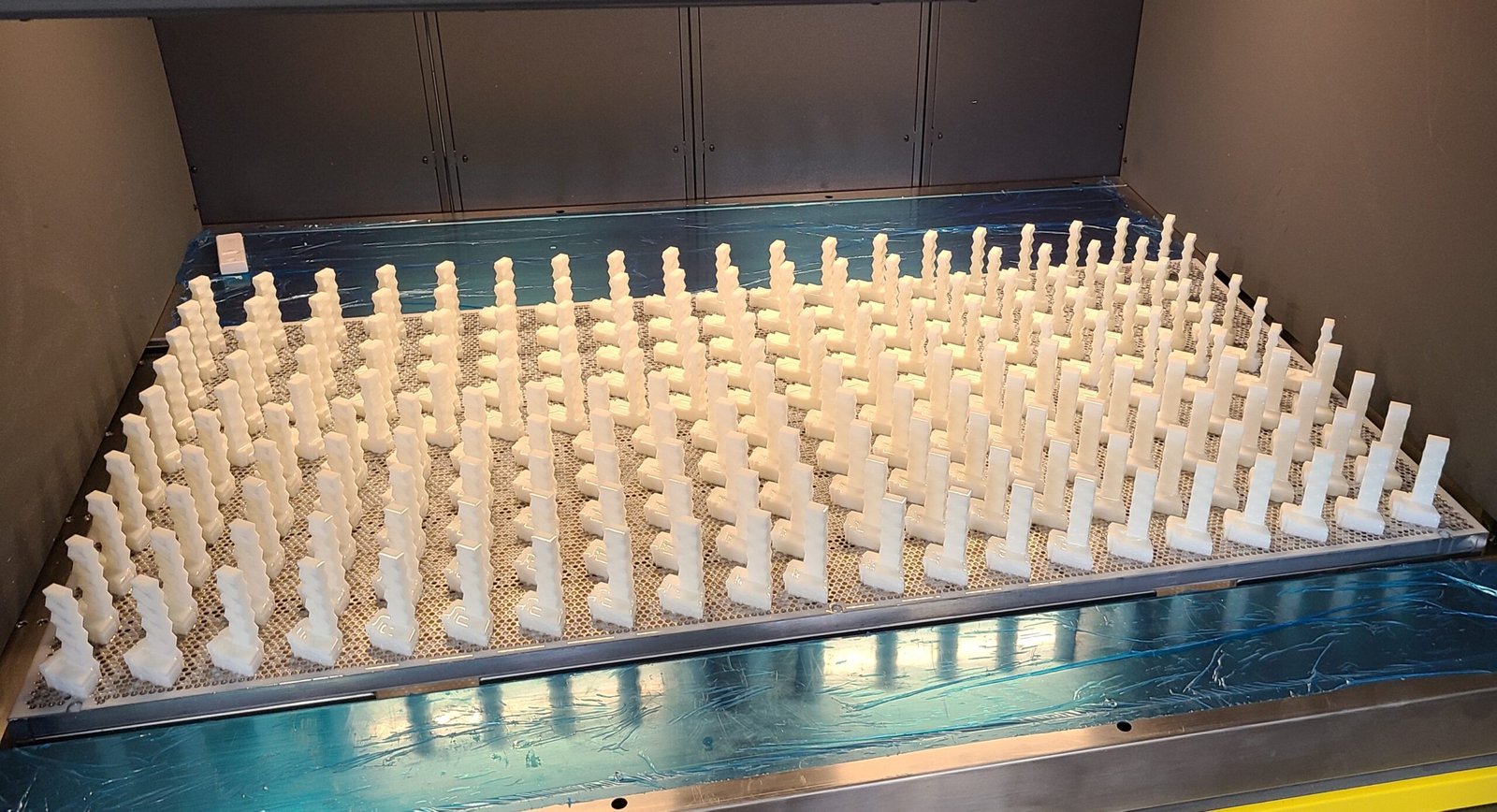

SLA (Stereolithography) is the original and our most frequently used process. It turns a liquid resin into solid plastic using a UV laser. The parts can be glued, sanded, dyed and painted. Common applications include form & fit, intricate geometries and cosmetic prototypes.

SLA(Stereolithography) is an additive manufacturing process that works by focusing an UV laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer aided design(CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat. Photopolymers are sensitive to ultraviolet light, so the resin is photochemically solidified and forms a single layer of the desired 3D object. This process is repeated for each layer of the design until the 3D object is complete

The future of Canadian electric mobility with help from Custom Prototypes

And the Rocketeer Award Goes To…

Cloudwalker